What are the maintenance procedure for standalone photovoltaic system. Equipment that is exposed to the environment for years will occasionally require maintenance as a result of corrosion and other factors such as wear and tear.

Introduction

Equipment that is exposed to the environment for years will occasionally require maintenance as a result of corrosion and other factors such as wear and tear. Thankfully, the maintenance requirements for photovoltaic power systems are quite simple compared to those carried out on a typical conventional power system such as diesel generators.

A photovoltaic system comprises of few mechanical components, as such there will be little need for adjustments. The maintenance program for a photovoltaic system should include the inspection of mechanical, structural and electrical components.

Owning a Standalone Photovoltaic System allows one to benefit from clean and low-cost energy produced by the solar system. Thus, carrying out a simple maintenance check on the system will ensure that your system continues to perform optimally thus, allowing you to reap the benefits for years to come.

The maintenance performed on Standalone PV Systems constitutes series of routine verification on inverters, batteries, cables, PV modules. These maintenance checks are carried out to guarantee and or ensure that systems continually perform optimally. Maintenance on a Standalone Photovoltaic System should be performed on a weekly, monthly and annual basis. The charger controller is to be checked weekly, the whole system, monthly and finally the panels, yearly.

Battery Maintenance

The battery is an important component in a standalone photovoltaic system design, thus, care for the battery is as important as the system itself. Battery maintenance is ensuring that the state of charge (SOC) of the battery is maintained.

The SOC is determined by simply measuring with the aid of a hydrometer, the specific gravity of the battery cells (if the battery is vented).

Other Areas of Focus for battery maintenance Are:

1. To check for corrosion on each terminal heads, clean the terminals and apply anti-oxidant petroleum jelly as necessary.

2. Inspect and observe the electrolyte level in each compartment and top up if necessary. Wipe electrolyte residue from the top of the battery.

3. Equalize batteries if the specific gravity difference between any cell is greater than 15.

4. Finally, check for sulphation (this involves the growth of lead sulphate crystals on the positive plate which in turn leads to a decrease in the active area and capacity of the cell).

To minimize sulphation, proper battery and array sizing, as well as periodic equalization of the batteries, is advised. It is important therefore to carry out these routine checks on a weekly, monthly, quarterly and annual basis.

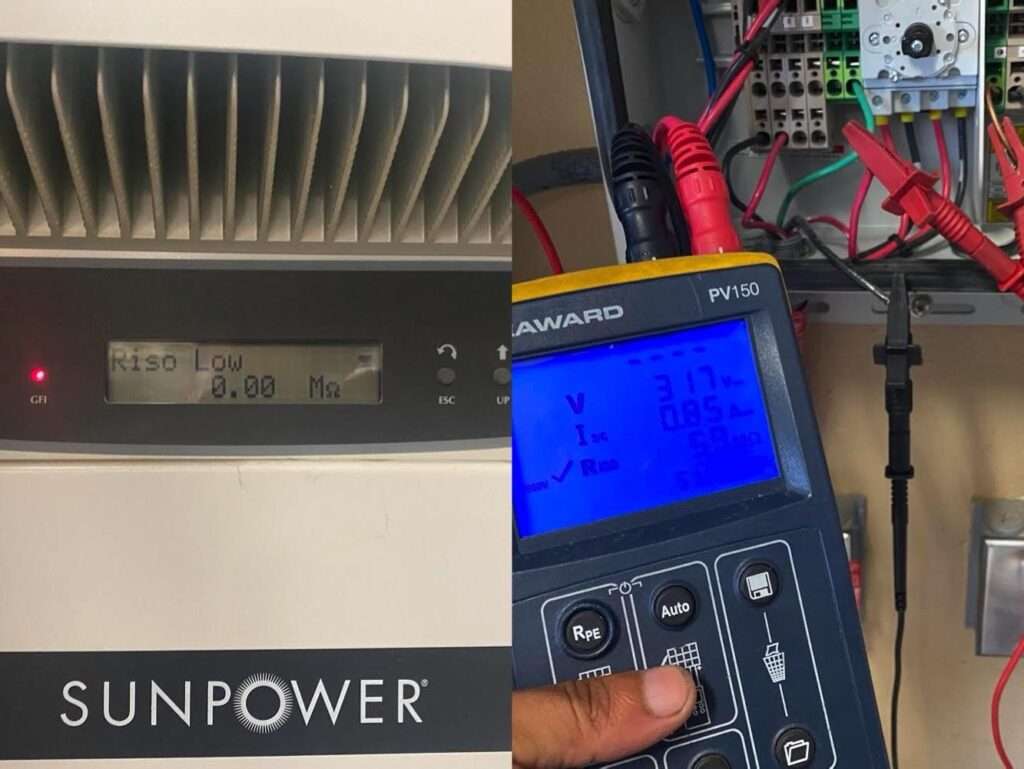

Inverter Maintenance

The inverter usually does not require major maintenance however, it is advised to check the inverter for dust accumulation and clean appropriately.

The fan and ventilation ducts should also be checked to ensure that the inverter is cooling and properly ventilated without obstruction.

Only trained and qualified personnel should be allowed to perform these checks. It is also advisable to perform this maintenance annually.

PV Array Maintenance

Inspect the array wiring for possible damage, excessive heat, looseness and tighten appropriately. The mounting structure should also be inspected for tightness. Verify that all bots are secure. Module surface should be cleaned using water and a soft cloth. This exercise should be performed early in the morning or wait till evening to avoid thermal shock. Confirm that no object is casting a shadow on the modules during the sun peak hours. Inspect and confirm that output (i.e. Isc, Voc, Imp and Vmp) from the array is as designed. Array maintenance should be done annually.

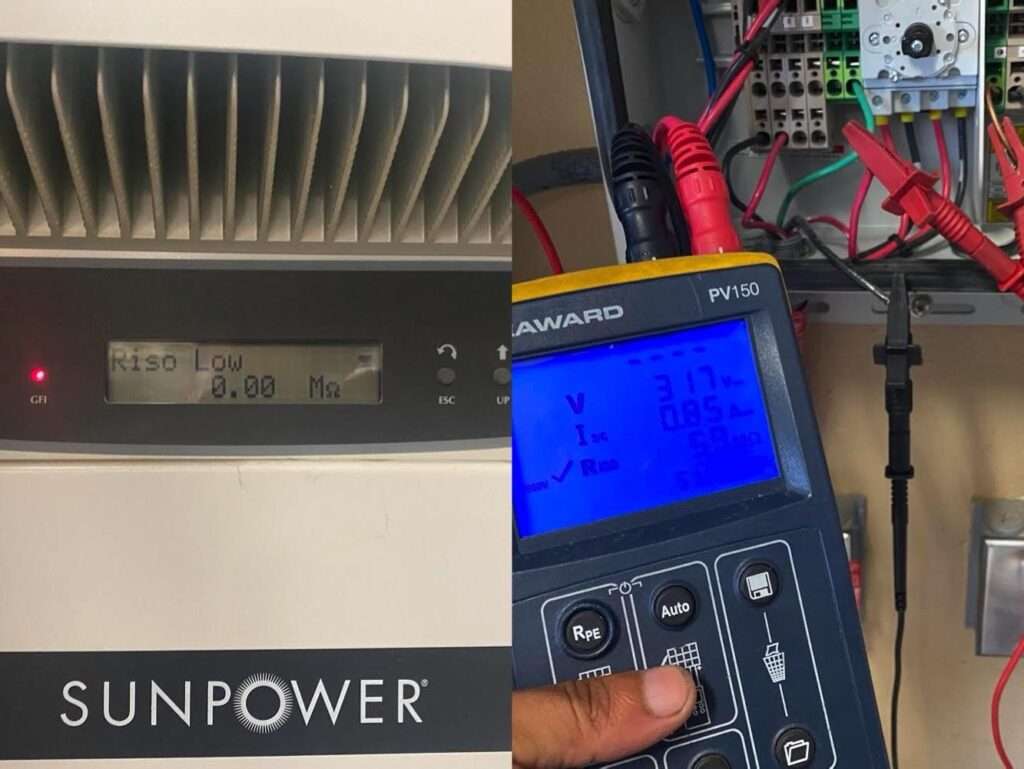

Safety Equipment Maintenance

Safety measures are put in place to protect the PV system. Features like system earthing, battery and AC breakers. It is important therefore to check and verify that all the safety equipment are functioning. If possible, perform a short circuit to check that the breakers are functional. Inspect insulating materials for wear and tear and replace if necessary. Inspect and confirm that the voltage drop is not more than 5% from the array to the battery and from the battery to load. If possible, measure voltage drop during normal operations.

Conclusion

In closing, all maintenance checks should only be performed by trained and qualified personnel. All maintenance activities should be carried out in compliance with all safety measures to avoid mechanical, electrical and other forms of hazards inherent to the job.